The marine industry is evolving every year, and companies in this sector need to build a massive infrastructure. They have to make an efficient and speedy transport of materials for business purposes. Moreover, this marine sector also plays a role in the development of other industries with its offshore drilling activities. However, one of the most important needs of this marine industry is material handling. To simplify the material handling process, companies in this sector have invested in marine cranes. In terms of function and design, these marine cranes ensure optimal safety and performance.

Mostly, marine rigging companies need to install cranes for lifting and hoisting operations. They use cranes to move heavy loads and transfer materials from and to marine vessels and barges. Heavy-duty cranes are useful for them to accomplish their marine and offshore activities. Marine crane manufacturers focus on the load conditions, stress, and the overall marine environment to design their material handling equipment. Especially, the loading capacity is the most important factor in choosing the right crane. You may also find variations in the crane capacity, as you need to mount cranes in different structures- ship-hulled, semi-submersible, and bottom-supported.

What are marine-duty cranes?

When you need to install the material handling system within 5 miles of the sea/ocean, you have to look for marine-duty cranes. However, you must not confuse them with maritime cranes that remain physically bolted to the boat, ship, water, and ground. The load lifting systems installed on the ship and boat should have gears to hold components near the sea. It may be much risky to install the crane systems on the shoreline due to the high water current and waves.

To ensure safety to your workforce, you have to focus on some factors-

- Water-current speed

- Distance from the sea

- Wind limit

- Sea-height limit

Marine Cranes - Know their applications-

Cranes designed for marine applications help in lifting and moving heavy cargoes and other materials from one site to another. To deal with the ship-to-shore activities, cranes are one of the most important tools.

You can install the crane on decks and other internal space of your vessels for a range of activities-

- Equipment transfer from other platforms and vessels

- Equipment shifting around the deck

- Equipment recovering and submerging in the sea and seabed

Although those crane systems are best for offshore sites, they can pose other challenges-

- Vessel stability and motion

- Sea force, weather, and wind

- Adjacent vessels and structures

- Seabed suction

Gantry Cranes for marine applications

You can move cargoes off and on ships dockside by using gantry cranes. These are tall cranes with massive designs to load and offload your ship. You can find a unique design of these cranes, as the operator’s cabin lies on the top. Moreover, high transparency is one of the most notable features of these cranes. The operator can check the way how the system is loading and unloading cargoes. However, with conventional cranes, you will not find this advantage, as the operator’s position is at the base.

Spreaders attached to these overhead cranes move out in a range of directions and latch onto a ship’s corner castings to lift the cargo. Modern overhead cranes are capable of lifting 4 cargo containers simultaneously, and that is why you can save time to unload your vessels.

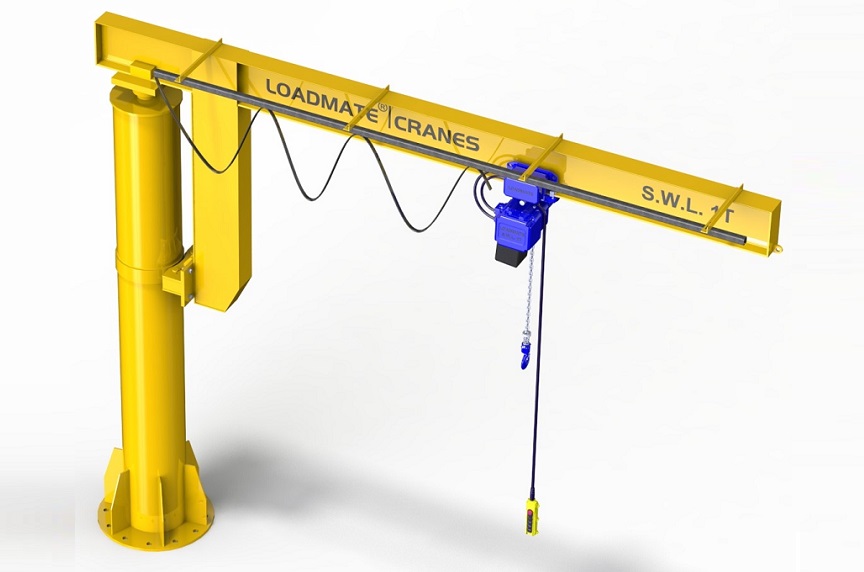

Jib cranes for marine sectors

The galvanized, freestanding jib cranes have a corrosion-resistant design, and thus, you can install them near the seashore. Manufacturers ensure that they have designed components for mainly marine applications. For instance, you need a NEMA 4X enclosure for the motorized boom rotation, as they protect wires from sea mist and saltwater. Still, you have to check out these features while choosing marine jib cranes-

- Stainless steel motors and other parts, like chains and brackets

- NEMA 4X in fibreglass/stainless steel designs

- Gearboxes with powder-coated structures

316 Stainless Steel can be the best material with optimal efficiency, as sodium chloride can be harsh to other metals. You must avoid aluminium for cranes in the marine sector. However, aluminium with an anodized surface coating is resistant to corrosion.

Buying the best marine cranes from manufacturers

- Some manufacturers will ask you to submit a written statement that-

- You will not use the marine-duty cranes near waves.

- You must not make the lateral shifting of loads and the boom.

- You should not drag the jib laterally.

When you think of having cranes on any water body and on the dockside, you will be responsible for its safety operations. You can take precautionary steps to configure material handling systems in the marine sector.

The marine industry is always unpredictable, and that’s why you have to identify the important variables to select the right type of cranes. For instance, ocean waves may have a high effect on your crane’s performance. Manufacturers focus on ocean conditions to construct their offshore drilling sites.

The most important is to talk to your crane suppliers and inform them about your material handling needs. They will help you with choosing the right cranes.